Savings Tools

How to Design Out Wire Form Costs With Natural Flow

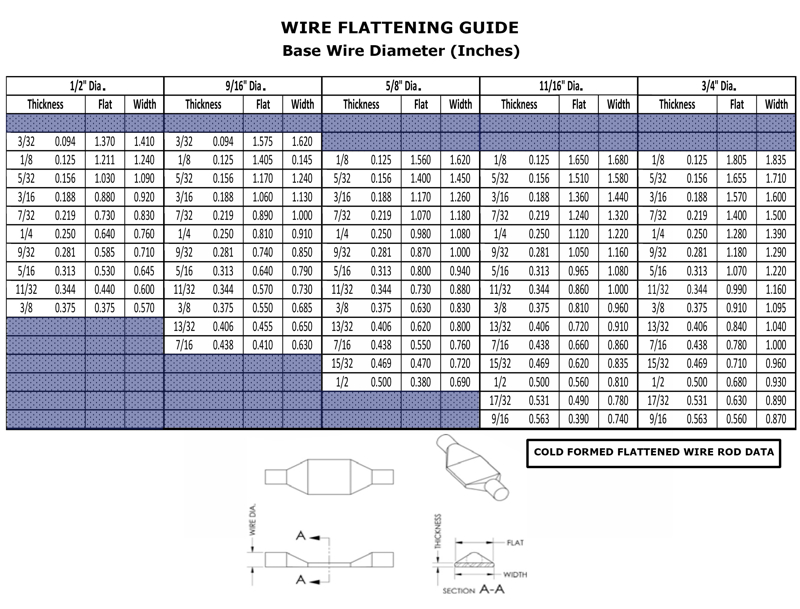

Flattening metal wire is often called crushing or planishing. This process is the result of pressure applied by use of a press. The press comes down, makes contact with the metal, then the material flows to the side. When designing a part, it is less expensive to allow for the natural flow of the material. This savings is achieved in two ways…

- The cost of the tool. Custom Flattening tools can be expensive

- The cost of an operation

If the width of a flattened part needs to be exact, it needs to be trimmed, which is created by a trim die. The operation of trimming can cause undue costs as well because it is another operation. If an exact dimension is integral to your design, consider asking for a tandem operation. In a tandem operation, the two parts are processed simultaneously. One part is flattened in the flattening station; a second part is flattened in the trim station. One stroke = 1 part. This is one way that Argo

Products is able to save its customers so much money.

There are a few rules of thumb:

- Maximum wire diameter that can be flattened by Argo Products is 1.25” diameter, C1008 CF wire

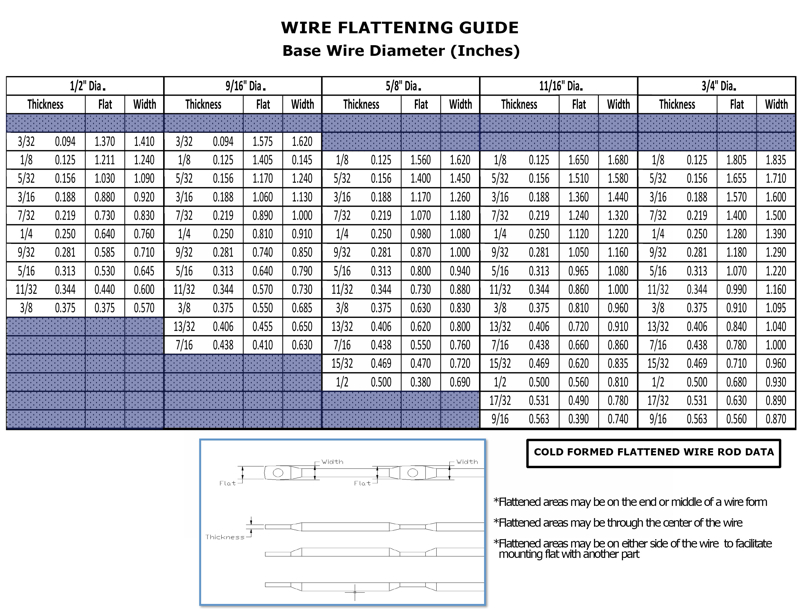

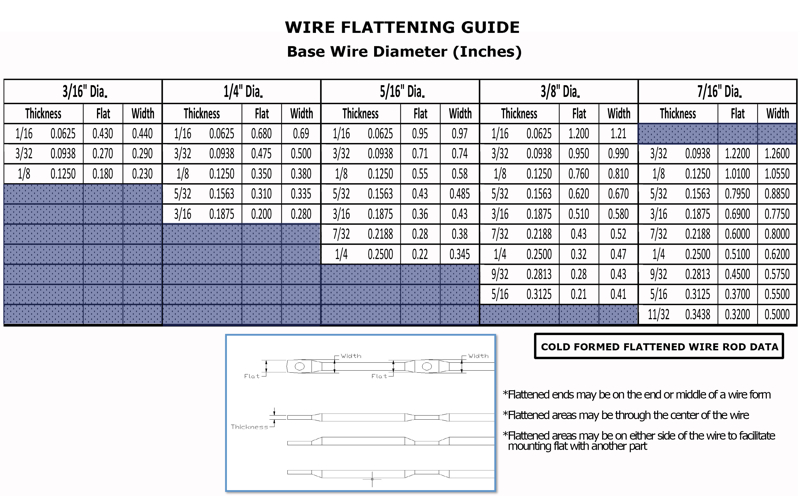

- The flattened width is a function of the thickness of the desired flattened area

- Minimum thickness is 30% of the wire diameter

- Both the flat and the width feature dimensions cannot be specified. Dimension one as critical, let the other float.

Argo Products Company is a low cost ISO 9001 value added, custom manufacturer of complex metal products using combined CNC Wire Formed, Stamped, Robotic Welded Assembly Solutions including Kitting, Pa..

Read MoreQuick Links

About Us Services Our Projects Certifications & Associations Wire Forming Metal Fabrication News Quality Assurance Job Opportunities Supply Chain Inventory Management Supplier Restricted Material Contact Us Privacy Policy© 2025. Argo Products Company, All Right Reserved. Industrial Website Design - WYSIWYG Marketing