Our Services

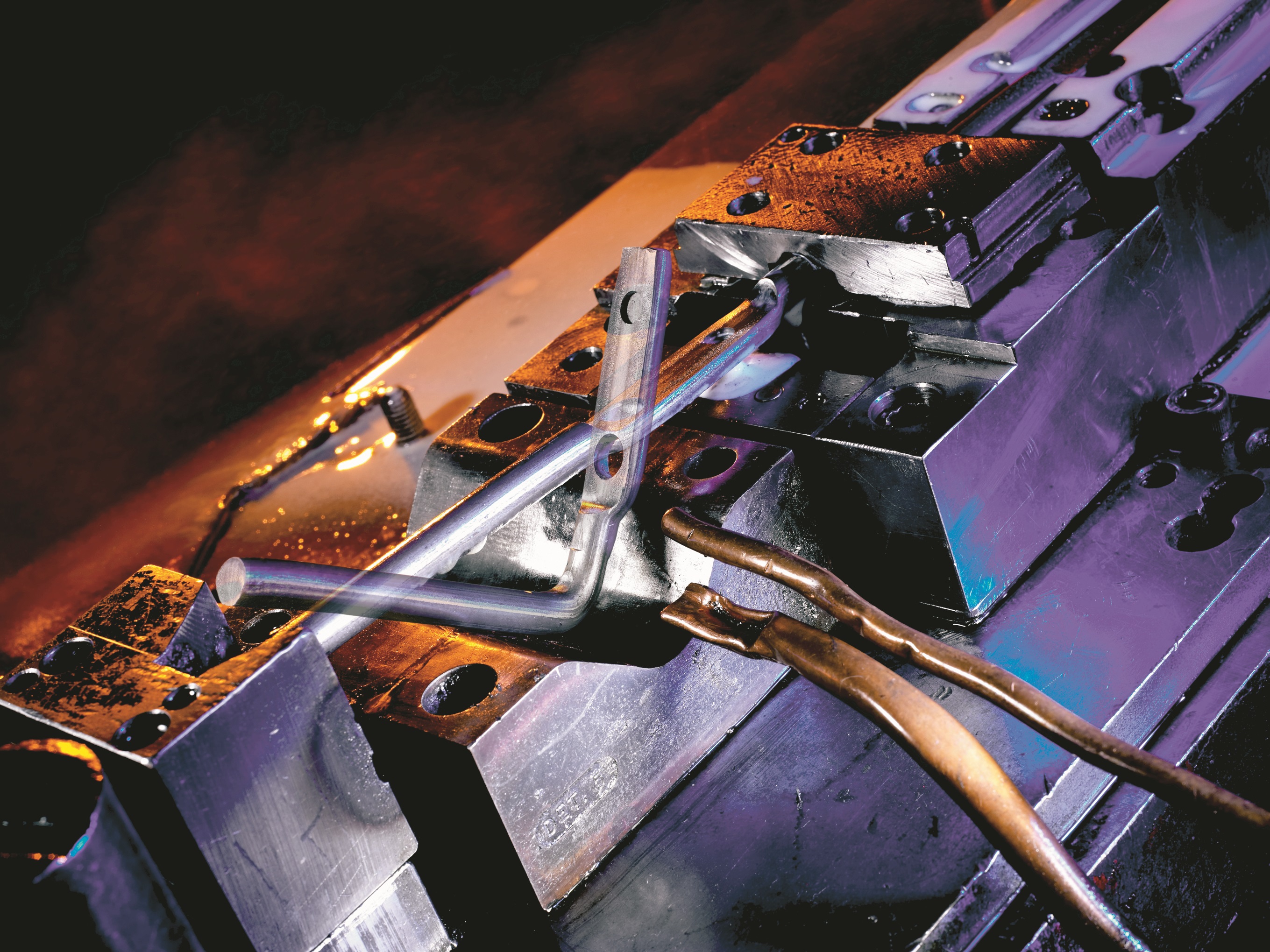

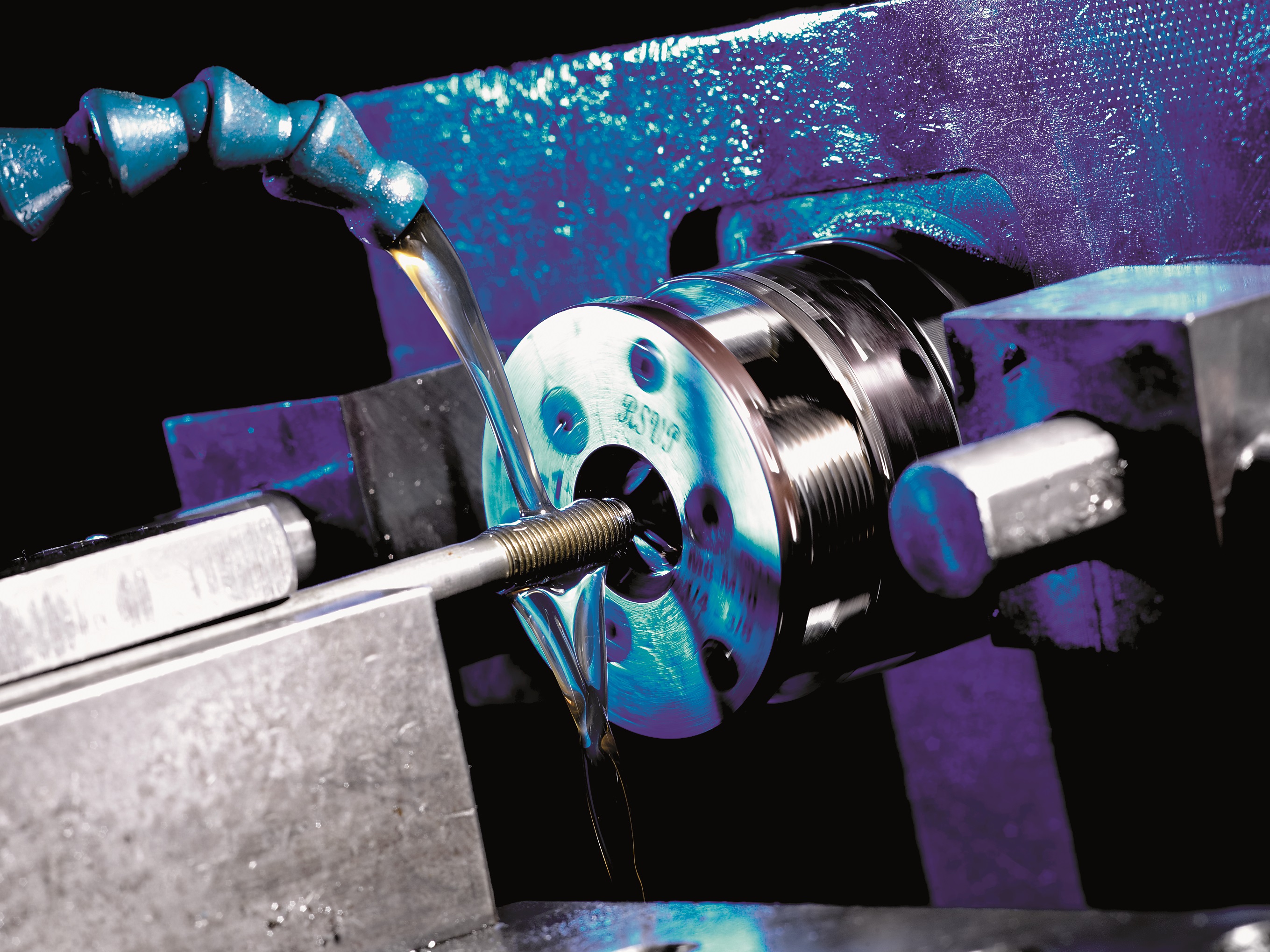

Stamping Services & Value Added Services

Capabilities

| General Capabilities | Contractor OEM Sub-Contractor |

| Press Rating | Automatic up to 300 Tons Non-Automatic 800 Tons |

| Press Speed | Up to 45 SPM |

| Maximum Press Stroke | 10 Inch |

| Maximum Press Bed Length | 84 Inch |

| Maximum Press Bed Width | 42 Inch |

| Maximum Part Length | 84 Inch |

| Maximum Part Width | 22 Inch |

| Maximum Part Diameter | 1.0 Inch |

| Maximum Part Weight | 100 Pound |

| Maximum Part Thickness | 1/4 Inch |

| Tolerance (+/-) | Up to 0.005 Inch |

| Equipment List | (1) 10' Shear (1) Computer Numerical Controlled (CNC) brake press (1) Plasma cutter (2) Auto indexing machines (2) Swage machines (3) Knuckle presses (3) Roll thread machines (30) Punch presses (4) Multipurpose drilling/tapping machines (5) Auto feed stamping presses (5) Hydraulic presses (6) Brake presses (8) Heading machines |

| Production Method | Die Perforated Metal Progressive Die Punch Press Sourced Lazer Sourced Turret Press Transfer Die Transfer Press |

| Material | Aluminum Brass Bronze Copper Nickel Stainless Steel Steel Titanium |

| Design Capabilities | AutoCAD (DWG) JPG SolidWorks |

| Additional Services | Assemblies Engineering Inventory Management Production Prototype |

| Industry Focus | Agricultural Lawn & Garden Medical Metal Chair Metal Chair & Furniture Transportation |

| Certifications | ISO 9001 Certificate |

Stamping Services & Value Added Services Fabrication Process

What is Metal Stamping?

Why is Metal Stamping advantageous?

Certifications

Stamping Service Equipment

- Over 60 – Presses ranging from high speed automatics to large bed blanking/drawing presses

- Up to 800 Ton Capacity with Bed Size to 48" X 72"

- Secondary operations including flattening, piercing, drilling / reaming, threading, chamfering, swaging, and clinching

Metal Stamping Services

Argo Products specializes in precision metal stamping services, focusing on the fabrication of custom metal components. Leveraging advanced technology and a skilled team, they offer accurate and efficient manufacturing using diverse materials. The company provides value-added services such as design assistance, prototyping, and tooling development. Argo Products maintains high-quality standards through rigorous inspection procedures and accommodates both high-volume and small-scale production. With a customer-centric approach, they deliver customized metal components tailored to the specific requirements of various industries.

© 2025. Argo Products Company, All Right Reserved. Industrial Website Design - WYSIWYG Marketing